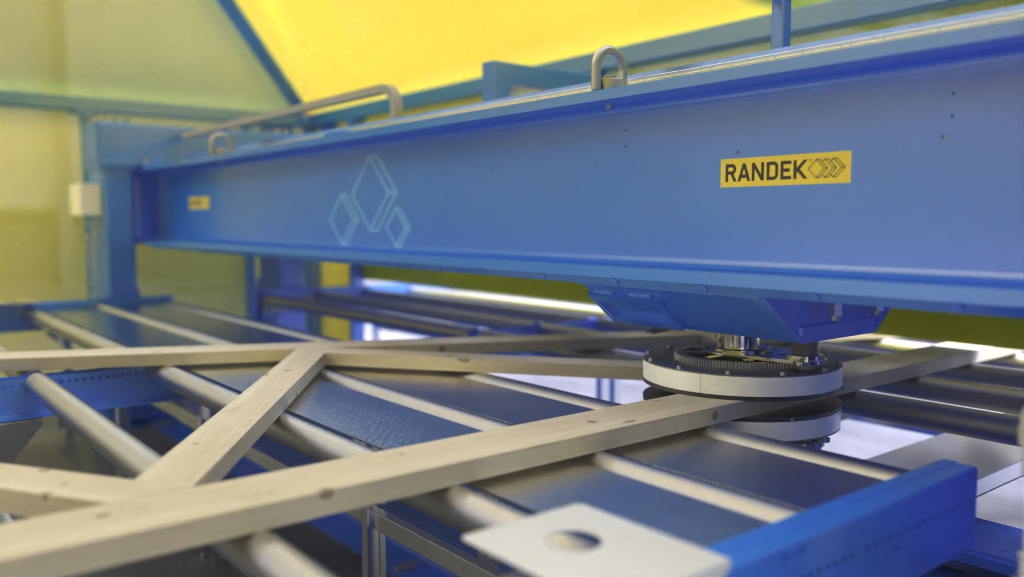

The company said it is one of the first UK trussed rafter brands to install the AutoEye manufacturing system from Swedish company Randek.

The AutoEye system will boost the capacity of trusses manufactured from the site while allowing more complex trusses to be produced in significantly less time, says Pasquill.

While the system itself won’t be installed until November, work is already underway to prepare the site ready for the machinery.

The AutoEye system helps to streamline the production process by visually identifying the joints in the truss, then picking, placing, positioning and pressing the nail plates with the required force, which is determined by the machine.

The system will offer up to a 50% time saving during manufacturing, which will support demand during peak periods, says Pasquill.

Pasquill hopes that automating the truss production process will free up workers at the Redhill site, allowing them to continue with other projects in the business.

Until now, Pasquill’s Redhill site has been operating at full capacity, but the introduction of the AutoEye technology is expected to double output for the same amount of labour.

Pasquill director Chris Powell said: “We are proud to be the first business in the UK to receive the Randek AutoEye Truss system. It will allow us to boost our capacity without the need for additional manpower, which is crucial as we continue to see a shortage of skilled workers in construction.

“We look forward to the installation of the automation system, and seeing the benefits it brings to us as a business, our customers and the wider house building industry.”